In the relentless pursuit of manufacturing excellence, 5-axis CNC machining has emerged as a transformative force, breaking through traditional production barriers and opening new frontiers in design and engineering. This advanced technology represents a paradigm shift from conventional manufacturing approaches, offering unparalleled capabilities that are redefining industry standards.

The Technological Leap

5-axis CNC machining's core innovation lies in its simultaneous multi-axis movement, which enables tooling to approach workpieces from infinite angles. This fundamental advantage translates into several critical benefits:

Revolutionary Design Capabilities

The technology liberates designers from manufacturing constraints, enabling the creation of parts with:

Complex organic geometries and free-form surfaces

Sophisticated internal channels and lattice structures

Compound angles and contours previously impossible to machine

Seamlessly integrated functional features

Unprecedented Precision Engineering

Through continuous toolpath optimization and maintained optimal cutting angles, 5-axis machining achieves:

Surface finishes that often eliminate secondary operations

Geometric accuracies within micron-level tolerances

Perfect feature relationships without cumulative errors

Consistent repeatability across production runs

Advanced Industries Transformed

The impact of 5-axis technology is particularly significant in high-tech sectors:

Space Technology: Manufacturing lightweight satellite components, rocket propulsion elements, and space telescope structures

Advanced Medical: Producing patient-specific surgical guides, complex orthopedic implants, and micro-surgical instruments

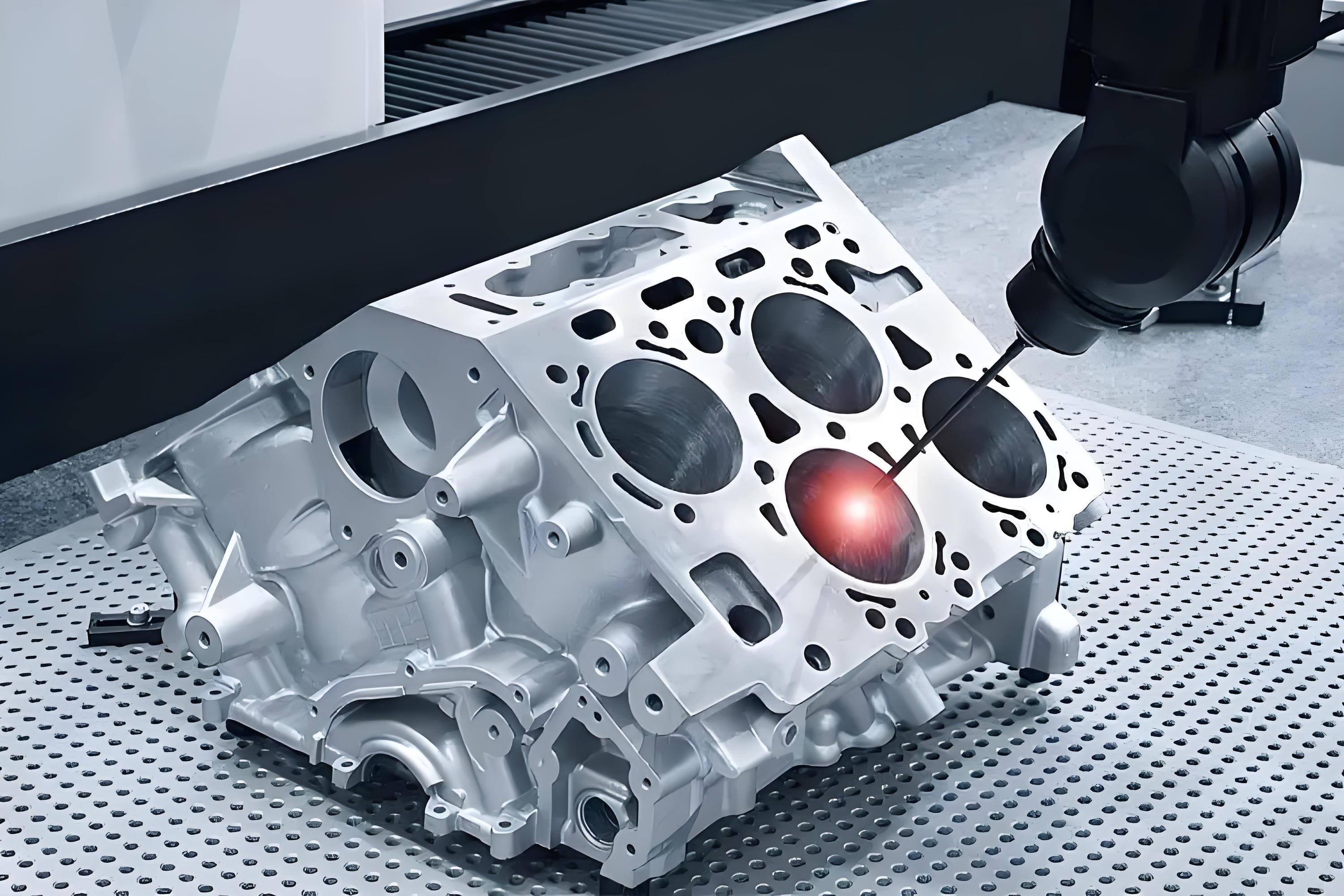

High-Performance Automotive: Creating optimized cooling systems, advanced suspension components, and lightweight structural elements

Precision Optics: Machining complex lens molds, optical mounts, and laser system components

The Digital Manufacturing Ecosystem

Modern 5-axis machining centers serve as the physical manifestation of digital manufacturing, featuring:

Intelligent Automation Integration

Robotic workpiece handling and pallet systems

Automated tool management and presetting

In-process measurement and compensation

Cloud-connected monitoring and analytics

Advanced Software Harmony

Sophisticated CAM programming with collision avoidance

Real-time simulation and optimization

Digital twin synchronization

Adaptive machining strategies

Sustainable Manufacturing Leadership

5-axis technology drives environmental responsibility through:

Significant reduction in material waste through optimized nesting

Energy-efficient machining cycles and strategies

Extended tool life through optimal cutting conditions

Elimination of secondary processing and associated resource consumption

The Future Vision

The evolution continues with emerging trends including:

AI-powered machining optimization and anomaly detection

Integrated additive and subtractive hybrid manufacturing

Quantum-metrology enhanced quality assurance

Distributed manufacturing networks with centralized programming

5-axis CNC machining stands not merely as a manufacturing method, but as a comprehensive solution that bridges digital innovation with physical precision. As industries continue to push boundaries in performance and efficiency, this technology remains essential for turning visionary designs into reality, proving that in modern manufacturing, complexity is no longer a constraint but an opportunity for innovation.